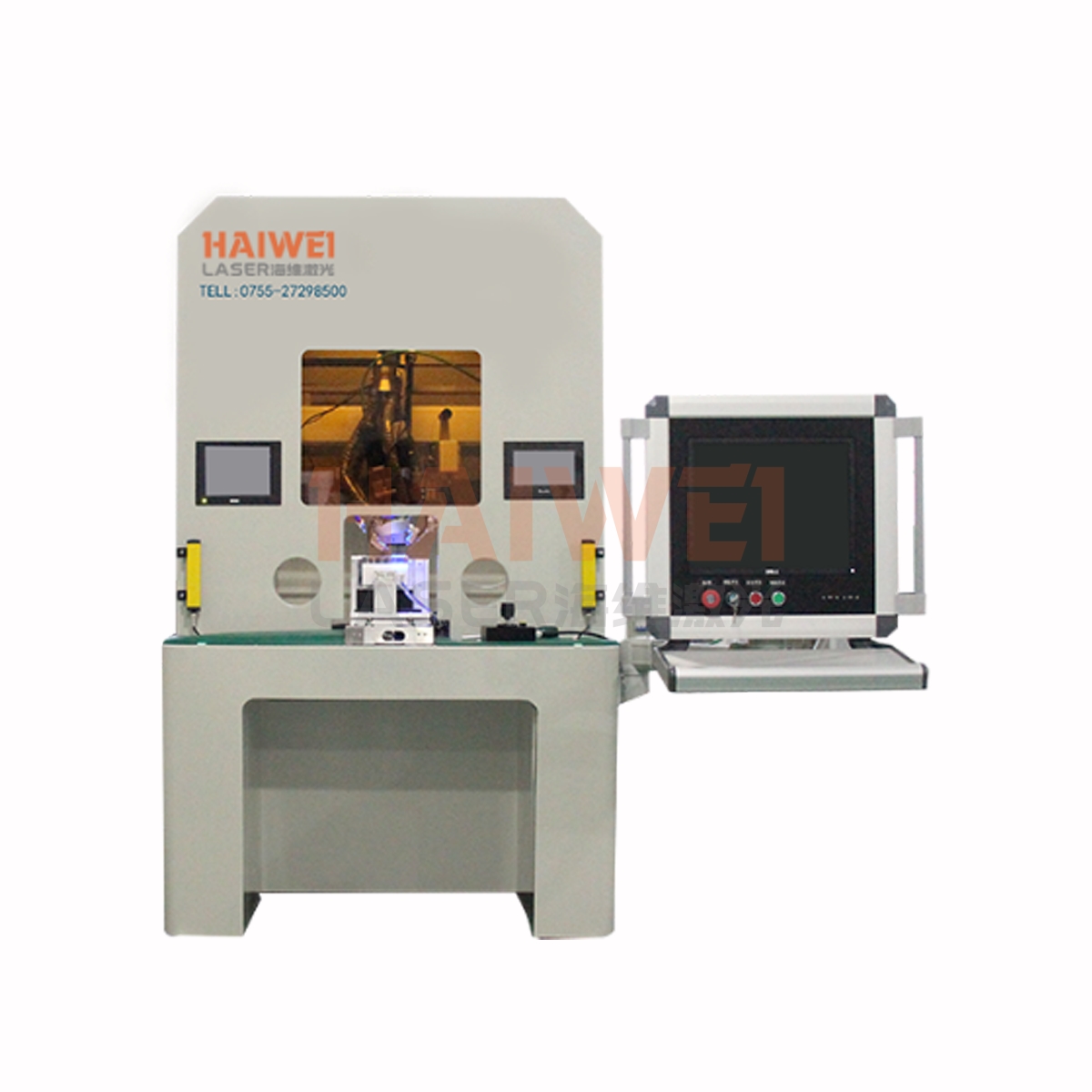

Laser soldering system

Product Series:Laser soldering system

Technical Support:Customizable

Application field:Suitable for electronic components spot welding, drag welding, sintering, heating and automation of special welding techniques on automated production lines, etc.

Introduction

Haiwei laser soldering machine system adopts advanced semiconductor laser, high-precision motion control system and precise tin wire feeding mechanism. Ensure the quality of each solder joint. It is suitable for electronic component spot welding, drag welding, sintering, heating and automation of special welding techniques on automated production lines, etc. It has the characteristics of real-time high-precision control of the temperature of the welding object, especially suitable for the existence of solder joints that cannot withstand high temperatures High-precision soldering of parts and thermal components.

| model | HW-FWD60 | HW-FWD100 | HW-FWD150 |

| Requirements of power supply | AC220V/±10%,50Hz | AC220V/±10%,50Hz | AC220V/±10%,50Hz |

| equipment power | 1KW | 1.2KW | 1.5KW |

| Laser power | 60W | 100W | 150W |

| Wavelength | 980nm | 980nm | 980nm |

| Work area | 300*200mm | ||

| input/output | I/O RS232 | ||

| Localization way | Red diode indicator (option ccd) | ||

| Feedback mode | Infrared feedback (optional) | ||

| Cooling way | Wind | ||

Samples More

Applications

Advantages of cooperation

17 years old brand factory direct sales

Haiwei laser welding equipment is directly sold by the factory. It has 17 years of resource advantage, and the same performance and quality are more favorable, which fully benefits customers and achieves win-win development.

Technical consultant 1 to 1 service

Provide consulting, diagnosis, optimization, maintenance and other services, and respond 24 hours a day, according to customer needs and produce customized products and solutions.

Comprehensive protection of customer rights

The mature after-sales service system allows customers to purchase with confidence, humanized service support, free proofing, installation training, upgrade and debugging, etc. to meet the diverse needs of customers.

Enabling products with unlimited value

Software and hardware are independently developed and designed, with mechanical design, software programming, electrical automation, parts processing, assembly and debugging, and after-sales teams, which can provide customers with professional maintenance, parts replacement, product upgrades and other technical services, and continue to create value for customers .